Industry News

New Engine for Intelligent Manufacturing: Six Core Technologies Reshaping the Future of Industrial Automation

Times:2025-08-04 Views:37

New Engine for Intelligent Manufacturing: Six Core Technologies Reshaping the Future of Industrial Automation

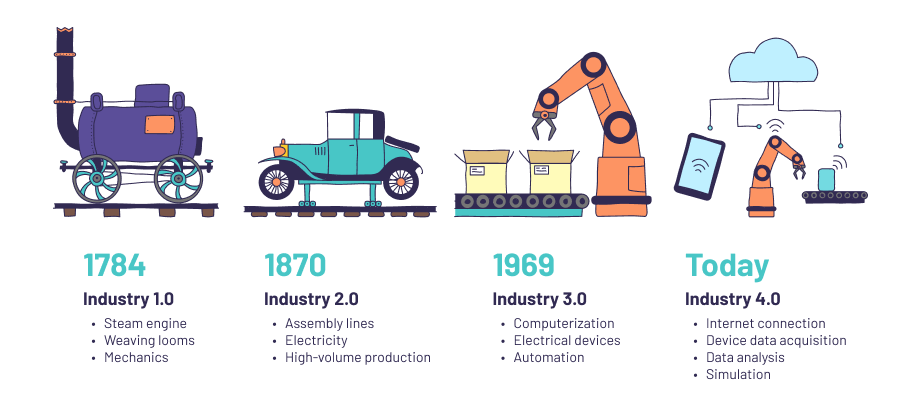

As a new round of technological and industrial revolution accelerates, industrial automation is entering a new phase. Global manufacturing is leaping from "equipment automation" to "intelligent system collaboration." In China, in particular, a "dual-engine" approach of policy-driven initiatives and scene-based innovation is unleashing unprecedented development potential in industrial automation.

Over the next five years, six key technological trends—from intelligent robotics and edge computing to low-code platforms and digital twins—will reshape the landscape of industrial automation. This article offers an in-depth look at the complete path of this "industrial intelligent transformation."

Trend 1: AI + Robotics, Moving from Solo Operation to Collaborative Intelligence

Collaborative robots (cobots) are rapidly emerging, replacing traditional "caged robotic arms" and becoming a new mainstay of flexible manufacturing. The new generation of robots is capable of safe human-robot collaboration, autonomous task perception, and adapting to complex working conditions, evolving from a mere "tool" into an "intelligent partner."

Take a domestic company, Zhidong Robotics, as an example. Its "PowerFlow" joint module has significantly increased torque density, allowing robots to deliver greater power in a smaller size, achieving a balance of lightweight design and high performance. This makes them suitable for high-frequency scenarios like logistics and 3C assembly. Furthermore, AI-enabled capabilities such as path planning, autonomous obstacle avoidance, and self-learning are moving robots from "solo operations" to "collaborative intelligence."

In high-precision manufacturing, the demand for servo systems is particularly stringent. For example, the HBDTECH H100S servo motor controller stands out for its excellent performance. It can achieve a positioning accuracy of ±0.01mm and a speed loop bandwidth of 300Hz, providing reliable driving assurance for instruments and equipment that require extremely high precision. This enables robots and automated equipment to achieve unprecedented precision and stability in assembly and processing tasks, pushing intelligent manufacturing to a higher level.

According to forecasts from multiple consulting firms, the global collaborative robot market is expected to exceed $10 billion by 2030, making it one of the core engines with the greatest growth potential in industrial automation.

Trend 2: Edge Computing Becomes the Distributed Nervous System of the "Factory Brain"

As sensors, PLCs, and industrial robots continuously generate high-frequency data, the traditional "upload to the cloud for analysis" model reveals shortcomings such as high latency, high bandwidth consumption, and low security. Edge computing has emerged as the "distributed nervous system" of intelligent manufacturing.

By processing data locally at edge nodes, not only can systems achieve millisecond-level response times and reduce network dependency, but they also enhance the robustness and local decision-making capabilities of factory systems. For instance, the HBDTECH PV550 photovoltaic water pump inverter incorporates the concept of edge computing. It features a built-in MPPT (Maximum Power Point Tracking) function to track the power output of solar panels in real-time. It also handles local processing of faults such as over-voltage and over-current, enabling efficient energy management in off-grid or hybrid-grid modes. This "plug-and-play" design greatly simplifies deployment and maintenance in scenarios like irrigation, livestock watering, and remote area water supply, making intelligent control possible directly on the edge device.

Future factories will no longer rely on a single "central brain," but rather on countless edge nodes collaborating to build an "instant-reaction" intelligent network.

Trend 3: Digital Twins Enable "Visible + Controllable + Predictable" Industrial Systems

The digital twin is evolving from a design support tool into a core productivity engine. By creating a real-time digital replica of a physical production system, companies can simulate processes, predict equipment status, and evaluate optimization strategies in a virtual space.

For example, leading companies like Baosteel and BYD have deployed "digital production line twin systems" in various manufacturing segments to achieve real-time monitoring of equipment health, remote maintenance, and dynamic production scheduling simulations. Digital twins are becoming the "front-end system" of industrial internet platforms, guiding manufacturing companies from a "reactive" to a "proactive" mode of decision-making.

This technology is also widely used in water resource management. The HBDTECH CPC-6D constant pressure water supply controller is a prime example. It can automatically regulate the start/stop and variable-frequency drives of up to six pumps simultaneously, with four of them supporting variable speed control, dynamically adjusting based on water level and pressure values. By simulating the operation of the water supply system in a digital twin environment, engineers can preset and optimize control strategies, ensuring stable and energy-efficient constant pressure water supply for municipal, hotel, and residential projects. This approach enables the advanced management model of "deploy in the digital space first, then implement offline."

Trend 4: Low-Code/No-Code Platforms Reshape the Industrial Software Development Paradigm

Industrial automation has an increasingly strong demand for software flexibility, customization, and rapid iteration. However, traditional development methods often have high barriers to entry, long cycles, and heavy maintenance burdens. Low-code and no-code platforms are now reshaping the industrial software development paradigm.

These platforms use graphical configuration and modular drag-and-drop features, allowing frontline engineers to develop lightweight industrial apps for equipment management, process monitoring, and fault reporting without needing extensive coding knowledge. For instance, a certain industrial large model has integrated low-code tools to provide "one-click" AI component support for developing MES and SCADA systems.

Trend 5: Acceleration of Industrial Large Models, "AI for the Factory" Enters the Mainstream

Unlike general-purpose large models, industrial large models place a greater emphasis on a deep understanding and intelligent processing of complex physical processes, production techniques, and multi-modal data.

The "Intelligent Manufacturing Brain" developed by a research institute has been applied in industries such as rail transit and photovoltaics, supporting precise early warnings for abnormal conditions and intelligent recommendations for process parameters. Another tech company has launched a "lightweight model inference engine" adapted for edge devices, enabling industrial control systems to run AI models even with low computational power.

As the domestic production of AI chips advances and model deployment costs continue to fall, AI will be embedded in every piece of factory equipment, much like electricity. From predictive maintenance to dynamic energy consumption management, "AI for the Factory" is moving from being "possible" to being "mainstream."

Trend 6: 5G + Industrial Ethernet Fusion Builds the "Connected Workshop"

Communication networks are the "nervous and circulatory system" of industrial automation. Over the next five years, the fusion of 5G and industrial Ethernet will build a connected workshop where all things are connected.

In "5G + Industrial Control" demonstration projects in Beijing Yizhuang and Guangzhou Nansha, AGVs, robots, and PLCs can already achieve millisecond-level control and remote programming. Combined with protocols like TSN (Time-Sensitive Networking), the communication network will upgrade from a "data transmission" tool to a core foundation for "real-time control," offering industrial-grade features such as extremely low latency, high reliability, and high determinism.

With "communication as control, network as programming," industrial networks are accelerating their transition from "tools" to "protagonists."